Palm sander purchasing advice: how to choose the right product

- What you need to know

- An orbital sander can be used to sand surfaces in order to round off edges or refurbish workpieces.

- Unlike random orbital sanders, orbital sanders have a rectangular sanding plate and are well suited for working on corners.

- The machines are powered by a battery or mains connection. Battery-powered sanders can be used more flexibly, but are usually less powerful.

- The heavier an orbital sander is, the more pressure it exerts on the surface. Lightweight models are therefore more suitable for delicate work.

- Ergonomic handles on orbital sanders prevent fatigue during sanding.

From old to new

Sandpaper is necessary to refurbish the wood of old furniture or to free garden furniture from the wear and tear of the cold months in spring. However, manual sanding can quickly become tedious, especially with large workpieces. Orbital sanders provide a remedy here and speed up the work process.

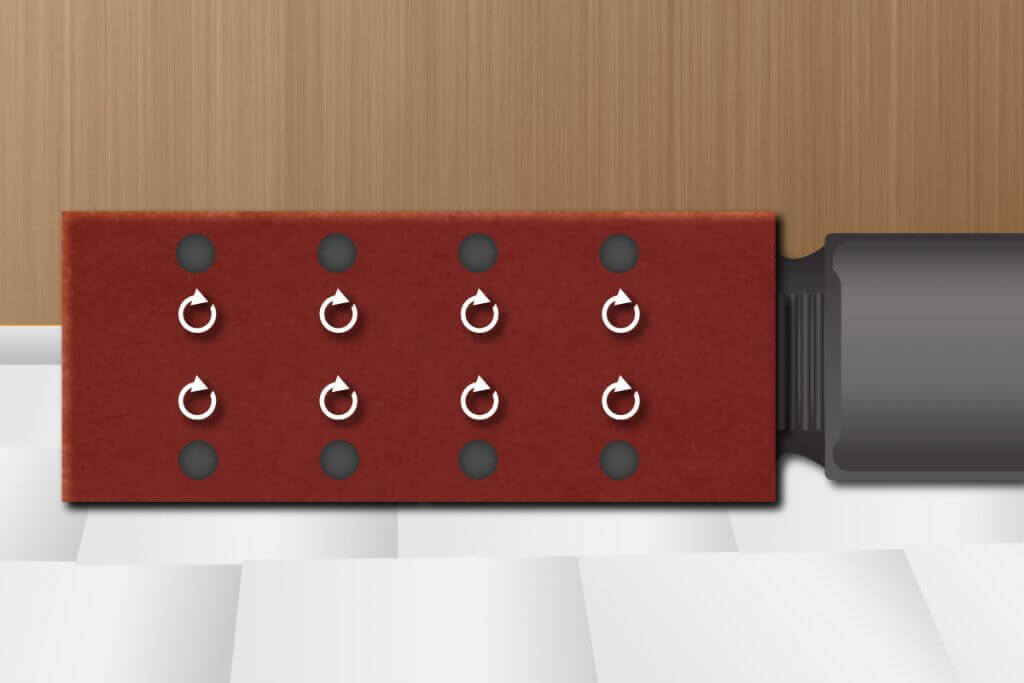

These are electrically or pneumatically operated sanding machines that are guided by hand. Their rectangular flywheel plate moves evenly over the surface to be processed and in this way takes over the tedious manual sanding. Orbital sanders are particularly indispensable for preparing larger surfaces. But they also offer support to hobby home craftsmen who attach importance to regularly maintaining their furniture and floors.

Thanks to the wide range of different abrasives that are attached to the flywheel plate by clamps or a Velcro bond, orbital sanders are suitable for many different materials. A sander can be used to treat both hard and soft wood floors, garden furniture, plasterboard, doors, wooden beams, glue and rust layers as well as metal surfaces. Orbital sanders are therefore ideal tools for removing old paint from furniture, for example, but they are also used for smoothing surfaces and for priming or fine sanding work.

How do orbital sanders work?

With orbital sanders, the rectangular flywheel is set in vibration. The vibrations imitate the hand movement during manual sanding. In this way, you create a fine material abrasion on furniture, tabletops and other sanding pieces thanks to the attached sandpaper. Orbital sanders are perfect for fine sanding in particular, as the abrasion is comparatively low. This makes them ideal for hobby DIYers who want a good result without having to practice a lot. Electric orbital sanders are powered either by a mains connection or a rechargeable battery. Mains operation ensures consistent performance, while battery operation allows for more flexible use of the sander.

What is the difference between orbital and random orbital sanders?

While the sanding surface of orbital sanders is rectangular, random orbital sanders have a round sanding surface. In addition, the sanding disc sits eccentrically on the drive axle. In addition to the circular motion, the sanding disc on random orbital sanders rotates; in this way you prevent fine hairline cracks in paintwork. Eccentric sanders are ideal for large-scale processing of workpieces with flat surfaces. Due to the higher pressure, they are more suitable for evenly removing paint or rust. For corners and edges, however, random orbital sanders reach their limits due to the round sanding plate.

For filigree work

Delta sanders have a triangular sanding surface, which makes them particularly suitable for precision work on corners and edges such as mouldings or stair treads. They are also the right choice for sanding pieces that need to be worked on with great care and attention.

What matters when buying an orbital sander

First and foremost, choosing the right sander depends on the intended use. For more delicate surfaces with edges and corners, an orbital sander is preferable to a random orbital sander. Inexperienced craftsmen are also better off using an orbital sander, as the abrasion produced is low. This reduces the risk of damaging the surface through incorrect handling. If you plan to use the sander outdoors, for example for the patio or garden furniture, it is better to go for a battery-operated model. Do-it-yourselfers who refurbish old pieces of furniture and wooden beams in the hobby cellar attach more importance to consistently high power in mains operation.

Power

The power rating of orbital sanders is also known as the power input; it describes the power of the built-in motor. A sander should have between 200 and 400 watts to cope with all everyday tasks. For harder materials, a higher power rating is needed. However, sanders with higher power ratings are considerably more expensive. In addition, machines with a high power rating consume more electricity. This means that battery-powered models need to be recharged more regularly. If you only want to do smaller jobs, you can also use less expensive grinders with a lower power rating of around 100 to 300 watts.

Vibration rate

The oscillating speed is the number of revolutions of the sanding surface per minute when the orbital sander is idle. The higher the oscillation rate, the higher the material abrasion on the workpiece.

Entry-level models have a vibration rate of up to 11,000 revolutions per minute. In the medium category, there are machines with up to 20,000 revolutions per minute, while professional machines can achieve up to 26,000 revolutions in the same time. However, such a high oscillation speed is only advisable for experienced craftsmen, as inexperienced users quickly run the risk of leaving sanding marks on the workpiece.

Grinding surface

The size of the sanding surface should depend on the surface to be sanded. For large surfaces, a correspondingly large sanding surface of about 115 x 230 millimetres is recommended to speed up the sanding process. Nevertheless, for larger surfaces you will need several working passes. For small surfaces, a sanding surface of about 100 x 150 millimetres is sufficient. This allows you to sand even hard-to-reach and angled areas cleanly.

Hardness of the sanding disc

Sanding discs are available in three different degrees of hardness: soft, medium and hard. The hardness of the sanding disc depends on the nature of the surface to be sanded. A soft sanding disc is best suited for curved and hard-to-reach sanding pieces, because here soft material can adapt optimally to the surface. Hard sanding surfaces, on the other hand, can be worked on faster and more effectively with hard sanding discs, as you can apply more pressure to the workpiece; in this way you also increase the material abrasion. Beginners who are getting used to working with an orbital sander should initially choose a softer hardness grade to minimise the risk of sanding marks. The medium hardness offers a good balance between precision and material abrasion.

Weight

The weight of sanders has a great influence on the pressure exerted on the workpiece. Therefore, this factor also depends on the DIYer’s level of experience and the intended use. The heavier the orbital sander, the higher the material removal rate. If you are inexperienced with sanders, you may have difficulty performing accurate sanding work with a heavy tool that weighs more than 2.0 kilograms. A lighter model weighing 1.0 to 1.5 kilograms is also recommended for use above head height, for example when sanding wooden beams, ceilings or walls.

Dimensions

Orbital sanders are about 10 to 30 centimetres wide, 10 to 45 centimetres long and 10 to 35 centimetres high. The dimensions and the weight are related: Larger devices are usually heavier. Small, compact devices are suitable for precise work and beginners who do not want to sand large surfaces. Large and heavy orbital sanders, on the other hand, are better for large surfaces that are easy to reach and do not require much effort.

Equipment and functions

Orbital sanders also have a number of other functions and features that can be helpful.

Dust extraction

Sanding causes abrasion of the material and thus also dust formation. This can quickly become a nuisance, especially when working in closed rooms such as a cellar. In addition, inhaling fine dust can have a negative impact on health. For this reason, many models offer a connection for a hoover directly on the unit. However, since such a device can become cumbersome, some orbital sanders are equipped with a dust catcher that should be emptied regularly after use.

Automatic speed control

This function allows you to adjust the speed depending on the surface or workpiece. The ability to adjust the speed on the orbital sander is especially important for DIYers who want to work on different surfaces. For coarser work, a higher speed is recommended, while filigree sanding work requires a lower speed.

Removable handle

Tools with detachable front handles also provide more flexibility. This makes handling easier in hard-to-reach places, for example, because you have a better view of the workpiece. Ergonomically shaped handles are also an advantage to prevent fatigue during longer work sessions.

Pressure sensor

Models with a pressure sensor are very practical, especially for beginners and do-it-yourselfers. Here, a built-in LED light warns you if you apply too much pressure to the surface. In this way, it helps you minimise potential damage on sensitive surfaces.

Protection for the eyes

In addition to a dust trap, you should definitely wear protective goggles when sanding wooden surfaces. Otherwise, whirled-up dust can get into your eyes.

Which sandpaper should I use?

The sandpaper has a great influence on the abrasion of the material and should therefore be chosen carefully before sanding. Sandpapers are available in different grit grades. Very coarse sandpapers have a grit grade of 6 to 30 and are particularly suitable for removing old varnish, paint and wallpaper. Scratches can also be easily touched up with such a low grit. Very fine grits of 1,000 to 7,000 are used for fine sanding on metal surfaces and car bodies, for example. The material of sandpaper for sanding machines is mainly made of fabric. It can be replaced depending on the intended use: The sandpaper is either clamped into the holding device or attached to a Velcro fastener.

Helpful tips for sanding work

Once you have chosen the right sander and the optimum sandpaper for your workpiece, there are still a few things to bear in mind when sanding in order to achieve the best possible result.

Movements

Make sure you make circular movements. This will reduce the risk of leaving unsightly sanding lines. Eccentric machines automatically perform rotating movements. On the other hand, with an orbital sander, the sanding disc must be moved manually to achieve the best sanding result.

Pressure

In combination with the number of vibrations, the grit of the sanding paper and the weight of the orbital sander, the pressure influences the abrasion of the material. For sensitive surfaces such as car paintwork, as little pressure as possible should be applied. However, if you want to remove paint residues from door frames, you will reach your goal faster with increased pressure.

Control

Controlled work is essential. If you are inexperienced or have little strength in your hands, you should opt for a compact, lightweight model. Ergonomic handles also help to ensure controlled handling.

Sanding direction

When sanding wooden surfaces, always sand in the direction of the wood grain. Otherwise, for example, if you sand across the grain, you will leave visible marks or damage the surface.

2,376 reviews

2,376 reviews