Sewing machine purchasing advice: how to choose the right product

- What you need to know

- Sewing machines are suitable for simple sewing tasks such as mending and shortening garments as well as for creative large-scale projects.

- With a sewing machine, seams are not only faster, but also cleaner and more durable.

- One of the most important buying criteria is the variety of stitches. The most common types of stitches include the straight stitch, the zigzag stitch, and the buttonhole stitch.

- Especially for beginners, it is also worthwhile to pay attention to certain additional functions such as an automatic buttonhole, a needle stop, and automatic thread tension.

- If you value numerous functions and automatisms, a computerised sewing machine is the right model for you.

- Cover and overlock sewing machines, which do the sewing, serging, and trimming in one go, serve as an additional device especially for sewing professionals.

The comeback of the sewing machine

For a long time, sewing was considered an old-fashioned hobby and mainly associated with the generation of grandparents. In the meantime, however, this image has changed drastically and needlework is experiencing a renaissance. In short: do-it-yourself is in vogue. After all, it makes a difference whether we buy something from the trade or create it according to our own ideas and thus create a unique item. An indispensable aid for such handicrafts is the sewing machine. With it, two layers of fabric can be joined quickly and easily, clothing and accessories can be worked on as desired or creative ideas can be implemented. It does not always have to be a large-scale project. A sewing machine is also suitable for simple sewing jobs such as making cushion covers and curtains or for alterations such as shortening trousers and minor repairs.

Depending on the equipment, a distinction is made between sewing machines for beginners, ambitious amateur tailors and sewing professionals. While sewing by hand is laborious and time-consuming, the sewing machine manages it in no time thanks to automatic thread tensioning and needle guides. But a sewing machine not only produces faster seams, but also neater, more accurate seams that look smoother and are more durable.

It can also be used on a wide variety of fabrics, from cotton and jersey to fine silks and thick denim, where hand sewing is almost impossible. Thanks to the free choice of fabrics, sewing enthusiasts can tailor their creations entirely to their personal taste.

With a sewing machine, it is therefore possible to make individual garments and textile accessories for the home. There are no limits to creativity – be it sewing utilitarian items such as bags and curtains, making children’s clothes or jazzing up jeans. Although the purchase of a new sewing machine is associated with high costs, this household appliance has a long service life, which makes the investment worthwhile. Because there is no need to go to the alteration shop, buying a sewing machine even saves money in the long run. Depending on the complexity of the sewing machine, a certain amount of training is required. Nevertheless, the advantages clearly outweigh the disadvantages, as the following table illustrates:

Advantages

- Time savings compared to sewing by hand

- Clean, robust sewing

- Automatic thread tensioning

- Free fabric selection

- Copes with heavy materials

- Production of unique pieces

- Money saving in the long run

Disadvantages

- Higher investment necessary

- Training required

The beginnings of machine sewing

Until the middle of the 18th century, trouser legs, dresses and bags were still sewn by hand. However, hand sewing with a needle, probably the most important tool for making garments, cost time and money. This gave rise to the idea of the sewing machine. In 1755, the German inventor Charles Frederick Wiesenthal filed a patent for a mechanical device that imitated the sewing motion of the human hand with a two-pointed needle that had an eye. In 1790, the Englishman Thomas Saint succeeded in making the first functional sewing machine out of wood, although it was only suitable for shoemakers. At the beginning of the 19th century, the German Balthasar Krems designed the first sewing machine with a needle that had the eye at the tip. However, a successful market launch did not occur until the manufacturer Singer in 1858.

The first machines were still driven without electricity by a foot pedal that set a mechanism in motion. In the beginning, they were still firmly connected to a table and the corresponding drive. Later, however, the much lighter and space-saving case sewing machines were developed. Today’s sewing machines do not have much in common with the first hand-operated devices. Unlike their predecessors, which were made of heavy wood or metal, modern sewing machines are largely made of plastic, which makes them easier to transport. While the machines of yesteryear only had a small number of sewing programmes, today machines with numerous computer-controlled programmes are available from companies such as Singer, Brother, Husqvarna, Pfaff, Veritas, Juki, Janome, Elna, Bernina, Toyota, and W6 Wertarbeit.

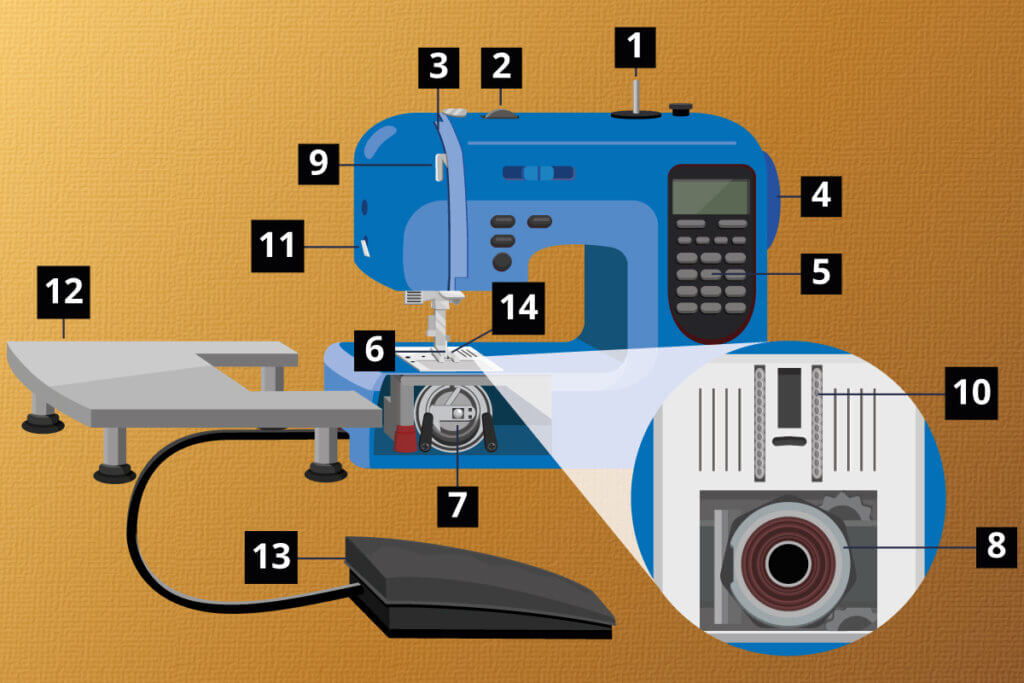

Functionality and components

On the housing of every commercial sewing machine there is a similar arrangement of different components. To make the first start-up easier, we explain the most important components of a classic sewing machine in the following section:

- Spool pins: one or more pins hold the upper thread spools.

- Thread tension knob: the knob on the top of the sewing machine creates and adjusts the thread tension if it is not automatic.

- Thread guide: the thread guide is a guide rail for the threads.

- Flywheel: with a turning motion, users set the needle in motion, which brings the bobbin thread up and places it together with the upper thread to the back.

- Stitch selection knob: stitches are usually selected manually at the stitch selection knob, sometimes by turning various wheels (for the stitch pattern, stitch length and stitch width). Computer-controlled sewing machines have a display that can be used to select the desired stitch.

- Sewing needle: since a different sewing needle is required depending on the material, it is interchangeable. Unlike a hand sewing needle, the eye of a sewing machine needle is at the tip.

- Hook: the hook has the task of gripping the upper thread loop, thus taking over the actual execution of the sewing movement.

- Bobbin and bobbin case: before sewing, users must wind the thread onto the bobbin. Then they place it in the bobbin case, which in turn goes into the bobbin case compartment (in the lower part of the machine).

- Thread lever: with the help of the thread lever, the required amount of upper thread is always released for the loop. Once the thread has gone around the bobbin case, the excess is pulled upwards. After it is pulled tight, the thread lever picks up another portion of thread, whereupon the next stitch is made.

- Feed dog: the feed dog pushes the fabric forward and presses the two layers of fabric together. Together with the thread lever, this results in the interlacing of the two threads. For finer fabrics or several layers of thick fabrics, we recommend using an upper feed dog in addition to the lower feed dog. If you want to switch off the feed dog while sewing so that you can move the fabric freely, you need a retractable feed dog.

- Thread cutter: on the back part above the feed dog there is a sharp hook that is used to cut the threads.

- Slide-on table: a slide-on table is sometimes attached next to the feed dog to ensure more space in front of the needle and can be removed if necessary.

- Foot pedal: the foot pedal, which is connected to a cable under the work table, is mainly used for the drive and sewing speed control.

- Presser foot and needle plate: the presser foot, together with the needle plate, holds the fabric in place and, in conjunction with the feed dog, ensures that it remains taut and does not slip. It can be raised to work with different types of fabric and is interchangeable depending on the sewing job.

The function of a classic sewing machine

The function of a sewing machine is obvious: it is used to mechanically produce a seam. But how exactly does the sewing process work? Although modern sewing machines are equipped with a variety of functions and features for different fabrics, the way they work is similar in all devices. Today’s standard sewing machines work according to the so-called lockstitch method, in which two threads, namely an upper and a lower thread, are linked together. The thread spool helps to guide the upper thread through the thread tension and thread it through a needle eye at the tip. Underneath is the bobbin with the bobbin thread.

The needle pokes through the fabric and creates a small hole; the upper thread is now underneath the fabric. The so-called looper then wraps the upper thread around the lower thread so that a loop is formed before the needle moves up again together with the upper thread. The looper thread is also pulled along through this loop. Thus, the loop is the point where the upper and lower threads are joined. As this point is in the hole that was previously pierced through the needle, the upper thread remains on the upper side and the lower thread on the lower side of the fabric. Finally, the loop ensures that the seam holds permanently and produces an even stitch pattern that looks the same on the front and back. To prevent the needle from stabbing the same place over and over again, sewing machines have a feed dog. This feeds the fabric a little further each time the needle goes up, with the help of a gripper arm and a gear wheel. The stitch type usually used is the straight stitch, but in principle several types of stitches are possible with this sewing method, such as zigzag stitches, utility stitches, and pattern stitches.

Types of machine

Sewing machines for home use are also called household sewing machines. These machines can be used for a wide range of sewing jobs, such as small repairs or new fabrications. In addition to this classic design, there are many other types on the market. First and foremost, the machine types differ in their operation and range of functions. Since sewing beginners are often overwhelmed by the choice, we offer them the following list of the most popular models to help them find the right machine. It doesn’t hurt to know in advance what the machine will mainly be used for. The sewing machine should not only be suitable for the specific purpose, but should also match your own skills.

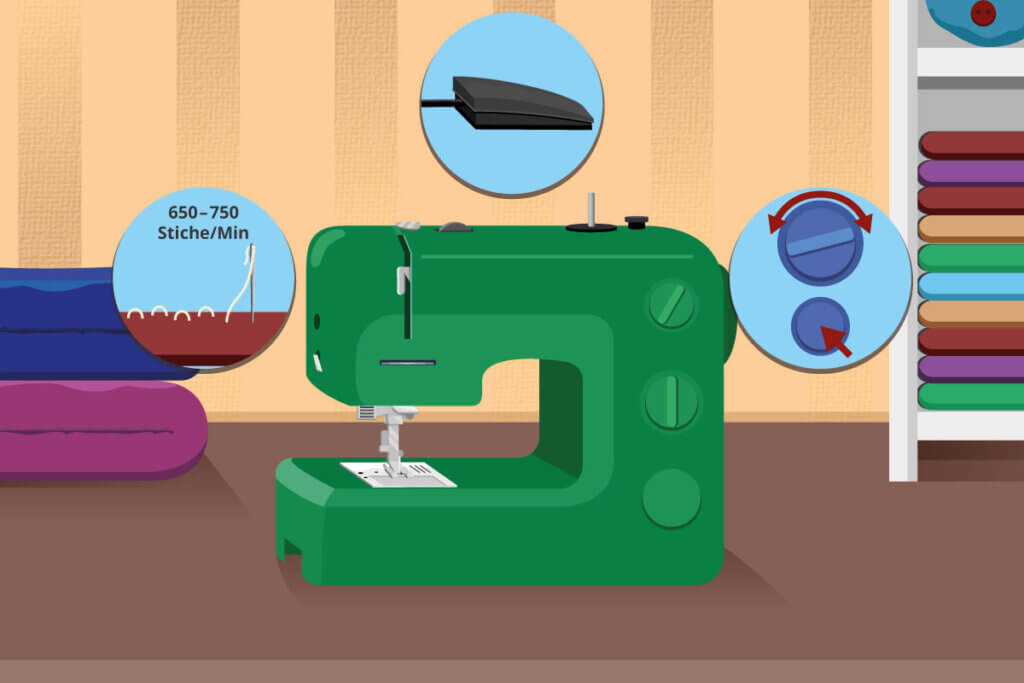

Mechanical sewing machines

If you have no experience of working with a sewing machine and would like to try it out first without incurring great expense, you should go for a simple mechanical sewing machine, as this has everything you need for sewing and is particularly suitable for beginners. Mechanical sewing machines are activated by a foot pedal, which users also use to regulate the speed. The sewing speed is usually between 650 and 750 stitches per minute. The foot pedal is operated electronically, but the stitch length and width as well as the thread tension are set manually on wheels and levers. Threading and adjustments to the respective fabric are also done manually by the user. Depending on the type of fabric, this can be a challenge for inexperienced users. Up to medium-firm fabrics, the use of a mechanical machine is possible without any problems. For those who do not want to do without automatic extras, there is a choice of models with additional electronic functions such as automatic thread tension or speed adjustment, in addition to the classic mechanical design.

The traditional machines are not only ahead in terms of price, but are also simpler in their mode of operation than their digital counterparts; the training period is correspondingly shorter. Mechanical machines also have the reputation of being more robust and durable. However, if something should break, users can usually repair them themselves. The downside of their simplicity, however, is the limited stitch selection (between 6 and 40 stitches), with mainly utility stitches such as the straight or zigzag stitch and fewer decorative stitches for embellishment. However, their concentration on the bare essentials is not necessarily a disadvantage. Basically, they have everything needed for larger sewing projects.

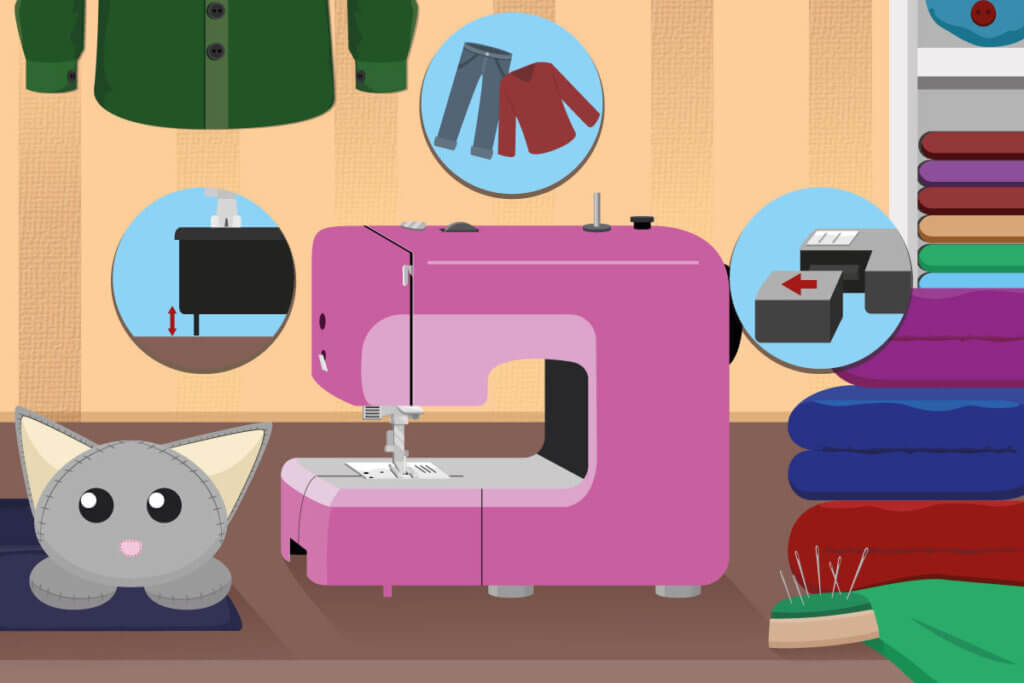

Computer sewing machines

For more elaborate sewing projects, it makes more sense to use a digital sewing machine, i.e. a computer sewing machine. These professional models, which were developed especially for industry and have now also found their way into the private sector, are equipped with a computer programme that electronically controls parameters such as stitch types, stitch length and stitch width, and also offers special features and numerous sewing programmes. For example, threading, tensioning and cutting of the threads are automatic, which saves time. Thanks to full automation, users also get the dreaded buttonholes evenly in one pass.

The stitch selection (between 30 and 600 stitches) includes not only utility stitches but also a variety of decorative stitches. The user can make very precise settings for the individual stitches via a (touch) display and control buttons. Decorative stitches with complex patterns such as lettering, flowers and animals can be transferred directly from the computer to the machine. Computerised sewing machines thus offer more precision than mechanical models. Finally, it is also possible to set whether the needle should remain raised or lowered into the fabric after a seam is completed, or whether it should be positioned centrally, to the left or to the right. With a working speed of up to 850 stitches per minute – usually infinitely variable – computer-controlled models are also much faster than mechanical sewing machines.

The handling of a computer sewing machine is often more comfortable than with the mechanical version, as it makes the optimal settings with regard to stitch length and width according to the selected sewing programme. This eliminates much of the work. However, especially for beginners, the many setting options can be more confusing than helpful. Compared to their mechanical counterparts, digital machines are also more susceptible to faults due to their technology. If a problem arises, it is usually unavoidable to seek professional help.

Free-arm sewing machines

So-called free-arm sewing machines, available in both mechanical and computer-controlled versions, are ideal for ordinary home use. They are not built into a table, but are designed to be used on an open surface. The name comes from the fact that the part of the sewing machine where the needle and hook are located is freely accessible. In contrast to built-in versions, free-standing models therefore ensure a larger working radius. This makes them suitable not only for sewing large pieces of fabric, but also for tubular pieces such as sleeves and trouser legs. This would be almost impossible without a free-arm sewing machine. Tight, round garments are simply slipped over the free-arm like a tube, making them comfortable to work with.

Some domestic sewing machines can also be converted into a free-arm sewing machine by removing part of the storage surface, or more precisely the sliding table. This creates the necessary free space between the table and the sewing machine.

Mini and travel sewing machines

Mini and travel sewing machines are basically the same as ordinary sewing machines and offer the same basic functions – with one difference: they are much smaller and therefore lighter. However, this also has a disadvantage: as they have less power than larger machines, they are hardly able to handle multi-layered or particularly thick materials.

The compact travel sewing machines are therefore, as the name already suggests, mainly designed as travel companions with a practical size and are only recommended for simpler sewing jobs. They can be used, for example, to carry out repairs or touch-ups while on the move. Battery-operated, they can be used almost anywhere without the hassle of a cable. They are also suitable for occasional sewers who have little storage space in their own homes. Due to their low purchase price and simple operation, they are also suitable for beginners. They can try them out first before investing in a large sewing machine. However, they are simply not suitable for more extensive sewing work and many or thick layers of fabric.

Overlock and coverlock sewing machines

If you often work with stretch fabrics like jersey or want to make serging easier, you should consider buying an overlock machine. The special feature of this type of sewing machine is the overlock stitch (also called overlock stitch), which comes from the words “over” and “to lock”. In an overlock stitch, the bobbin thread blocks the upper thread so that the seam cannot come loose. Unlike conventional machines, overlocks are operated with several needles and up to five thread spools. For a long time, these professional sewing machines were mainly used in industrial textile production and allow you to sew the fabric layers, clean up the edges, and trim the seam allowances in one operation, resulting in a very neat seam and no fraying of the fabric edges. With the appropriate equipment, you can sew not only zigzag stitches but also other types of stitches. In addition, seams with several, for example different coloured, threads or special hems and flatlock or rolled hem seams are possible.

So-called coverlocks also sew and overlock in one step. However, while overlocks can only work on one edge of the fabric to sew two pieces of fabric together, coverlocks can also sew in the centre of the fabric. They are not equipped with a knife for this. However, neither a coverlock nor an overlock is suitable as a sole sewing machine, as not all sewing operations are possible with them. For example, they do not have the option of a straight stitch. They are more profitable as an add-on to a normal sewing machine.

The specialists among the sewing machines

The trade also offers special sewing machines such as quilting, felting and embroidery machines. However, buying one is only worthwhile for someone who quilts, felts and embroiders. As a rule, modern, computer-controlled sewing machines already have the appropriate programmes.

Purchase criteria

When choosing a suitable sewing machine, the focus is not only on the type but also on the range of functions, performance and handling. To avoid unnecessary expenditure, consumers should consider exactly what they need the sewing machine for before buying. Is it mainly alteration work, smaller sewing projects or complex own creations? Depending on the intended use, the choice of sewing machine will be different. For starters, simple models that are easy to operate are often sufficient. If the user is overwhelmed with the operation of the machine, the fun of sewing is quickly lost. Experienced sewers, on the other hand, appreciate a wide variety of stitches and sewing programmes.

Handling and comfort

For beginners in particular, it is important that the sewing machine can be operated intuitively so that they can quickly get into the hobby. While computer-controlled sewing machines are equipped with a display, mechanical models have rotary dials for setting the stitch type, width and length. The display should be large and illuminated with LED lights so that all the information about the current settings and the corresponding symbols are easy to see. The symbols should be as self-explanatory as possible. Ideally, there is a brief overview below the control panel with all the selectable stitches and the corresponding numbers. Otherwise, it would take a lot of time to search through the operating instructions for every little setting. If there is no display, consumers should make sure that the buttons and levers are user-friendly enough to make operation easy.

Those who cannot afford the luxury of their own sewing room or want to be mobile with the machine should pay attention to the lightest possible weight. A lightweight sewing machine is much more flexible to use. Furthermore, the larger the machine, the more space it takes up on the table or in storage. Portable machines, usually suitcase models, are often equipped with carrying handles and an integrated accessory compartment, so that needles and thread are always at hand. In addition, the compact sewing machines are easy to set up or put away.

Most sewing machines operate with a power of 50 to 70W. For heavy fabrics like jeans and leather, they need to be particularly powerful. However, powerful machines can be quite noisy. If the machine is not to be located in a separate hobby room, it is advisable to pay attention to the noise level when choosing a purchase. Comparable to a spinning washing machine, the vibrations of some sewing machines can also spread to the flat next door. Mechanical models are usually louder than computer sewing machines. A non-slip soundproof mat can help.

Stitch types

Depending on the sewing machine model, there are different types of stitches, including utility stitches, stretch stitches and decorative stitches. The stitch variety of a sewing machine varies between 6 and 600 stitches, although 100 different stitch types are not necessary for ordinary use. How many programmes are ultimately recommended depends on your own requirements and the sewing machine’s field of application. The most important stitches to have are the straight stitch, sometimes known as the lockstitch, the zigzag stitch, and the buttonhole stitch. These three types of stitches can be used for almost all sewing jobs:

Straight stitch

The straight stitch is the standard for topstitching and sewing together. As an all-purpose weapon, it is most often used, not only by beginners. With the exception of buttonholes and neatening seam allowances, almost any sewing job can be done with this stitch. With a larger width or length setting, it can even be used for tucking or tucking.

Zig-zag stitch

The so-called zig-zag stitch, also an all-rounder, serges cut edges with two intermediate stitches each and is suitable for decorative seams or even for setting a bartack. Whether the fabric is firm or stretchy, the only important thing is that the beginning and end of the seam are locked. This stitch type can also be used for topstitching stretchy fabrics such as jersey.

Buttonhole stitch

The buttonhole stitch is used to sew around a buttonhole and saves many sewers time and nerves. It is also suitable as a decorative stitch, for example for attaching patches. The small nodules that form on the cut edge protect the buttonhole, which is subjected to a great deal of stress as the button is pushed through.

Other types of stitches are not essential, but optimise the performance of a sewing machine. The most common stitches include the following:

Elastic stitch: the elastic or stretch stitch is ideal for sewing elastic fabrics, such as children’s hats or sportswear, and topstitching elastic bands that need to remain particularly tight but still stretchy.

Double chain stitch: the looped stitch formation and the larger thread input per stitch provide elasticity, especially for small stitches.

Quilting, decorative, and ornamental stitches: these stitches are used for decorative sewing or embellishing several layers of fabric.

Reverse stitching: reverse stitching is mainly used for bar-tacking seams.

Stitch length and width

A sewing machine should not only be able to adjust the stitch type, but also the stitch length and width. While the stitch length influences how loosely or tightly the fabric is sewn, the stitch width regulates the horizontal expansion of the stitch.

Additional functions

With the most important stitch types, sewing machines already have the necessary basic equipment, but one or two additional functions can make sewing even more convenient. The following relieve sewers of tedious work:

Automatic buttonhole

Insert the button into the buttonhole plate, place the sewing material underneath and off you go: thanks to automatic sewing and serging, buttonholes of different sizes can be easily and quickly fitted into a garment. The automatic buttonhole function is indispensable especially when a lot of garments and bed linen are on the agenda. With it, consumers do not have to turn the fabric or adjust the stitch length and width by hand. A distinction is made here between the 4-step automatic buttonholer, where users set the selector switch to the numbers 1 to 4 one after the other, and the 1-step automatic buttonholer, which is more suitable for larger quantities, as only the starting point needs to be marked on the fabric.

Controllable needle stop

This stop function allows you to adjust the position of the needle in or above the fabric. Sewers can therefore choose whether or not the needle should remain in the fabric after finishing a seam. If a needle stop with a low needle is set, the piece of fabric cannot slip even when the presser foot is raised. If the needle stays in the fabric, it is easier to sew curves more evenly or the fabric can be turned more easily.

Automatic thread tension

Some machines offer the option of setting the thread tension automatically. This is particularly useful for sewing beginners, who often have problems with the correct setting, and is also very practical for delicate work. The automatic thread tensioner keeps the thread at tension so that it is centred and neither on the top nor on the bottom. However, in the event that this does not fit (for special processing techniques), a manual setting should always be possible in addition to the automatic setting.

Automatic thread cutter

A built-in thread cutter saves sewers from having to fiddle around with scissors to cut a thread. It is not to be confused with the thread cutter, which is on the side of almost every machine. Here, the sewing machine cuts the upper and lower threads at the touch of a button. However, this also requires precise positioning of the handwheel.

Twin needle

Twin needles (special sewing machine needles with one plunger but two separate needle tips) are useful for reinforcing seams and hems or for adding special accents. Because of the two tips, two spools of thread are needed. This allows you to sew straight stitches with two threads on the upper side, while a zig-zag pattern is created with one thread on the lower side. The two parallel seams ensure a professional look and a firm hold. Even jersey fabrics can be hemmed quickly and easily.

Adjustable presser foot pressure

Adjustable presser foot pressure helps to handle both very thick and very fine fabrics. It ensures that, for example, thick denim or woollen fabric has enough room and is pushed on powerfully, while it minimises the pressure on thin fabrics so that the sewing machine does not attack the delicate fabric. Depending on the model, they have a rotary switch to regulate the foot pressure.

Threading aid

For all those who regularly despair when threading the thread, an integrated needle threader is useful. Users first pull the thread through the separate threading aid, place it on the sewing machine and pull the threader up to the height of the needle hole. Then they turn it clockwise to the back before turning it back again. When the thread is in the hole, pull with your fingers and you are done threading. Here it is important to make sure that the needle is of good quality so that the threading aid works.

The right equipment

Depending on the price range, the sewing machine comes with more or less accessories. The following applies: Beginners in particular should have a good range of accessories in addition to the sewing machine. Which accessories you need depends on the specific purpose of the machine. The trade offers everything that sewing enthusiasts need, from needles and thread to bobbins and scissors. No matter which accessories consumers consider important, they should make sure that the parts are compatible with their sewing machine.

The following accessories should not be missing if you want your first sewing attempts to be successful:

Needle

There is a suitable needle for every sewing project. There are universal needles, jeans needles, jersey or stretch needles and leather needles. To start with, a pack of conventional machine needles in different sizes is usually sufficient. Often, such a set is already included with the sewing machine. Universal needles are suitable for all firm, non-elastic fabrics. Jeans needles are used for firm materials and so-called stretch needles for working with elastic fabrics such as jersey. Leather needles are specially designed for soft to medium-weight leather. It is important that the needle is of high quality so that it does not break off during sewing. If the needle is too thin, it could break; but if it is too thick, it may destroy the fibres of the fabric.

Yarn

Many sewing machine models already contain two to three spools of thread. But not all thread is the same: since cheap thread often breaks, consumers should invest in a good cotton thread or a high-quality polyester thread instead. Probably the most common all-purpose yarn, polyester is particularly uncomplicated. It does not shrink when washed and remains tear-resistant when ironed. Cotton yarn, on the other hand, is not elastic and should accordingly only be used for non-elastic fabrics. A collection of threads in different types and colours guarantees that sewing machine owners are prepared for any sewing situation.

Scissors

If you want to sew, you need a good pair of scissors to cut the fabric. Household scissors are not sufficient here, as they must be particularly sharp and cut smooth edges. Accordingly, fabric scissors should only be used to cut fabric, otherwise they lose their sharpness. In addition to the tailor’s or fabric scissors, a smaller pair of handicraft scissors and embroidery scissors for cutting off protruding threads and for making the finest cuts are also part of the basic equipment. A rotary cutter is also useful. It consists of a blade wheel that is clamped in a plastic handle. It is ideal for making long, straight cuts.

Other equipment that comes in handy when working with the sewing machine:

- Bobbins: the bobbins contain the bobbin thread. To avoid having to constantly rewind the thread, it is a good idea to use several bobbins. This way, sewers always have the most important threads already on one bobbin.

- Seam separator: this consists of a plastic handle with a pointed metal spike sticking out of it. The sharp point can be used to unpick seams if a part has slipped during sewing or if you have sewn something else.

- Marking pens: marking pens, such as tailor’s chalk, fabric paint pens or magic markers, are used to draw patterns. It is practical to simply wipe or tap off the chalk when you have finished.

- Pins and staples: Pins and fabric clips are helpful for holding the pieces of fabric in place so that they do not slip when sewing.

- Measuring tape: a measuring tape is indispensable when taking exact measurements, for example, when determining the circumference of the body.

- Buttonhole rail: this is a tool for making buttonholes. It is used to move the presser foot back and forth while sewing.

- Zip foot: a zip foot helps to create perfectly sewn-in zips by allowing you to sew very close to the tooth edge of the zip.

- Cutter mat: especially when using a rotary cutter, a cutting mat is essential to protect the surface from scratches.

- Transport cover: a protective transport cover is recommended to keep the sewing machine safe when travelling.

- Sewing templates: with a basic set of sewing templates, beginners in particular will always have the most important patterns to hand so they can get started straight away.

- Filling cotton wool: if you want to stuff cushion covers or stuffed animals, you should ideally always have some filling cotton wool at hand.

Cleaning, oiling, maintenance

If the sewing machine is not properly cared for, problems will quickly arise. On the other hand, if you clean your machine regularly, you will not only achieve better results, but also increase its lifespan. But what needs to be taken into account when cleaning and caring for a sewing machine?

On average, a sewing machine should be cleaned every four weeks; however, it is ideal to clean the machine after every ten hours of use. Over time, dust fluff, lint, and crumbs accumulate inside the machine, which can impair its function. As a result, the upper thread breaks, the bobbin thread gets tangled or the fabric no longer feeds. For thorough cleaning, we recommend a soft, clean fabric, sewing machine oil, brushes, cotton buds, a screwdriver and a hoover, among other things. The following step-by-step instructions show how users can best proceed:

- First, unplug the machine before disassembling it into individual parts. To do this, remove the needle plate (with a screwdriver or just a little pressure, depending on the model) and the needle. Then remove all accessories such as the bobbin, thread, thread reel holder and presser foot. On some machines you can also remove the hook system.

- The next step is to clean the inside of the machine from thread remnants, crumbs and dust. A hoover is best for this. Use a brush or cotton swab to remove the last remnants from the corners and other hard-to-reach places.

- Clean the hook path and the bobbin area with a soft cloth. For particularly stubborn dirt, use a little sewing machine oil on a cotton bud.

- While the hook area of electronic computer sewing machines must not be oiled at all, oiling is actually necessary for mechanical models. Only special acid- and resin-free sewing machine oil should be used for this purpose. It is also important to use the oil sparingly: One or two drops are sufficient.

- After cleaning, reassemble the individual parts.

- Finally, clean the exterior: Dust can be removed particularly well with a soft cloth.

With the following tips, the machine will last even longer:

- When cleaning, remember that the inside of the sewing machine must never get wet. Do not use a damp cloth.

- If you regularly use a cover, the sewing machine will stay clean longer and save you some cleaning.

- Care or maintenance also includes changing the needles regularly as soon as they become blunt or crooked. The interval depends on the use and the scope of the sewing projects.

- Finally, it also makes sense to look under the needle plate from time to time to see if dirt has accumulated there.

In addition to regular cleaning, a professional inspection or maintenance by the manufacturer is also required. How often this should be done depends on the extent of use. If the machine is used daily, for example, it is advisable to have it inspected every one to two years, while if it is used only occasionally, maintenance every three to five years is sufficient. Mechanical machines are less prone to breakdowns than computer sewing machines, so professional maintenance is not necessarily required if the machine is still working without problems. Manufacturers often offer the option of sending in the machines to carry out the repairs themselves.

Images 1-20: © FinalCheck

17,851 reviews

17,851 reviews