Summer tire purchasing advice: how to choose the right product

- What you need to know

- According to the O-O rule, summer tyres are intended for the period between Easter and October.

- Their special tread, combined with their harder rubber compound, is perfect for warm temperatures and dry as well as rain-soaked roads.

- Buyers have the choice between different versions: Summer tyres are namely available as a complete version, without rims and as a runflat edition with run-flat properties.

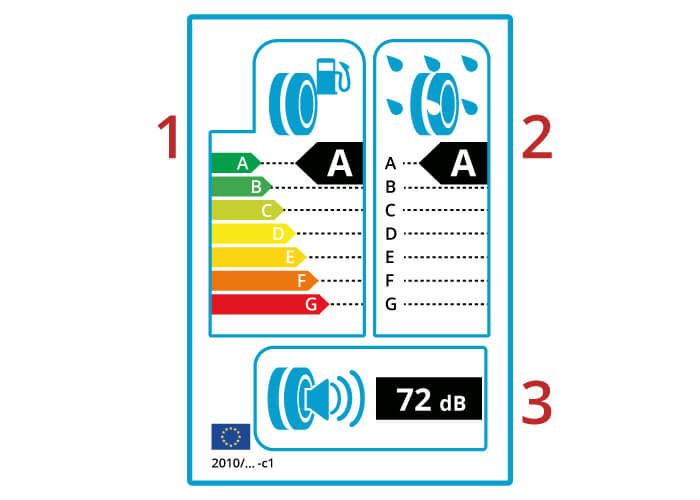

- The EU tyre label informs consumers at a glance about fuel efficiency, wet grip and external rolling noise.

- The DOT number tells drivers the date of manufacture and thus the age of the tyre. Experts recommend changing summer tyres after six years at the latest.

Is spring here? Now summer tyres are due!

The last piles of snow have finally thawed away and the temperatures are persistently rising into the double digits – then it is high time for a tyre change. Since the material of winter tyres is too soft for warm temperatures, it quickly reaches its limits as soon as spring calls. So if you don’t have all-season tyres, don’t cut corners and fit summer tyres that are optimised for driving on dry as well as wet surfaces in warmer weather. Their special tread and harder rubber compound provide better grip on the road. This increases safety and reduces fuel consumption.

When is it time to change tyres? The O-O rule

Summer tyres are a rubber compound specially designed for warm temperatures and do not provide sufficient driving safety in winter. Since the rubber hardens when temperatures are too low and grip on smooth asphalt decreases, they must be replaced with winter tyres in autumn. But when is the right time?

Tyre mix or uniformity?

When fitting summer or winter tyres, it is important to ensure that the same tyres are always fitted on at least one axle. However, it is more advisable to use the same tyres on all four wheels.

In the law, § 2 para. 3a StVO only stipulates a situational winter tyre obligation, which depends on the road conditions: “In case of black ice, slippery snow, slush, ice or frost, a motor vehicle may only be driven with tyres which fulfil the characteristics described in Annex II No. 2.2 of Council Directive 92/23/EEC of 31 March 1992 (M+S tyres)”. So there is no clear regulation.

At the latest in spring, when constant temperatures above seven degrees Celsius prevail, it is time to adapt to the changed weather conditions. A rule of thumb, also known as the O-O rule, recommends that summer tyres should be fitted at Easter. In October, they can be replaced by winter tyres – of course, taking into account the temperature and weather conditions prevailing at that time. If it snows again after Easter, cars with summer tyres must remain stationary, as otherwise a fine and a point in Flensburg may be imposed.

A look at the tread: What does the legislation say?

The change of season is not the only reason to change tyres. Of course, drivers should also keep an eye on wear. Here it is important to pay attention to the tread depth. For brand-new summer tyres, a tread depth of eight millimetres is standard. Retreaded tyres, on the other hand, usually have a shallower depth. While a minimum tread depth of four millimetres is prescribed for winter tyres, 1.6 millimetres is sufficient for summer tyres. It often makes sense to change tyres before this limit is reached. The ADAC, for example, considers a minimum tread depth of 2.5 millimetres to be sensible in order to avoid aquaplaning – the floating of the tyres on wet roads – as far as possible. Already at less than three to four millimetres, grip in wet conditions decreases, which increases the risk of accidents.

Robust, comfortable, fast and economical: the advantages of summer tyres

Many drivers leave their winter tyres on the rims all year round – partly out of convenience, partly out of forgetfulness. But why is it advisable to buy summer tyres? Compared to winter tyres, summer versions have the following advantages:

- Robustness: Thanks to their harder rubber compound, summer tyres wear less at higher temperatures than their winter counterparts. With the same wear and tear and a mileage of about 10,000 kilometres, summer tyres, for example, manage up to 2,000 kilometres more.

- Driving stability: Compared to winter tyres, summer tyres offer more driving comfort. Especially in high temperatures or at high speeds, they score with easier handling and more steering precision due to their materials and tread structure.

- Shorter braking distance: Due to their better wet weather properties, summer tyres have a shorter braking distance in almost all driving conditions. For example, at 20 degrees Celsius and a speed of 100 kilometres per hour on a dry road, summer tyres need about 18 metres less (38 instead of 56 metres) than winter tyres to come to a stop.

- Reduced fuel consumption: The harder summer tyres have a lower rolling resistance and therefore hardly wear out in summer. With them, drivers consume less fuel, which saves them money. Since summer tyres are not only good for the wallet but also for the environment, it is advisable to switch to them when the temperatures are right.

The most important purchase criteria, from the tyre label to the ECE test mark.

Ideally, a summer tyre has good fuel efficiency and scores with excellent grip, even on wet roads. But what other criteria play a role in choosing the right summer tyres?

The most important things at a glance thanks to the EU tyre label

Since 1 November 2012, an EU regulation on labelling (1222/2009) has applied to tyres. It is mandatory for cars of class C1, certain light trucks of class C2 and some trucks of class C3. The regulation applies to tyres manufactured after 30 June 2012. The EU tyre label provides information on the fuel efficiency, wet grip and rolling noise of a tyre. The mandatory information is intended to enable buyers to see the most important properties at a glance.

Fuel efficiency

Fuel efficiency, also known as rolling resistance, is particularly important for those who want to save money. The easier the wheels turn, the less energy is needed and the less fuel is consumed. Rolling resistance is divided into classes A to C and E to G and shown as a symbol with a petrol pump; class D is not used so that higher-quality tyres can be clearly distinguished from lower-level models. The fuel efficiency class indicates how economical the tyres are in terms of fuel consumption. Class B, for example, consumes 0.1 litres more per 100 kilometres compared to class A. Class E even consumes 0.14 litres more. Nowadays, most tyres fall into classes B and C.

Wet grip

The wet grip of tyres refers to the properties and thus also the safety during emergency braking on wet roads. It is divided into classes A to C and E to F, with classes D and G not used. Summer tyres with good wet grip have a short braking distance on rain-soaked roads. There are differences of up to 30 percent between the best (A) and the worst class (F). This means that during emergency braking on a wet surface at a speed of 100 kilometres per hour, the braking distance is extended by up to 30 metres. The wet braking performance is shown as a rain cloud symbol.

External rolling noise

As drivers like to open the window, especially in summer, the external rolling noise is also quite important. It indicates how loud the tyres are when passing. The value refers to the volume outside the car.

The external rolling noise, also called rolling noise or external driving noise, can be recognised by the number of black quarter rings next to the loudspeaker symbol as a decibel value:

- 3 rings: The limit value is complied with.

- 2 rings: The limit value is complied with or undercut by up to three decibels.

- 1 ring: the limit value is undercut by more than three decibels.

Depending on the car tyre, different noise limits exist, which is why the combination of rings and decibel values varies. The average value is about 70 decibels, which is roughly comparable to the noise level of a running kettle.

When tyres mature: The DOT number

The age of the tyres also plays a role in the purchase decision, as the rubber material hardens and becomes brittle over time, causing the tyres to lose quality. For this reason, since 2000 consumers have found the production date as a four-digit number in an oval on the tyre sidewall, the so-called DOT number. The abbreviation DOT stands for the US Department of Transportation, which introduced the number. The first two digits indicate the production week, the last two digits the production year. For example, a tyre with the DOT number 2316 was manufactured at the beginning of June 2016.

Safe on the road: The ECE mark

If the tyres bear the ECE mark (“Economic Commission for Europe”), buyers can be sure that they have been produced in accordance with the European standard ECE-R 20 for passenger car tyres. The test mark is shown either as an “E” in a circle or as an “e” in a rectangle on the sidewall of the tyre. Since the production date of 1 October 1998, the mark has even been compulsory according to § 36 para. 7 StVZO; only retreaded tyres are exempt. The TÜV classifies the absence of the test mark as a serious defect.

ADAC and GTÜ

If you want to be on the safe side, both ADAC and GTÜ offer tyre tests that provide extensive information on driving characteristics. There, consumers can check how the product of their choice performed.

How to find the right tyre size

Once you have found a tyre that meets all your requirements, you have to make sure that it fits the vehicle in terms of size and construction. The wrong tyres will not only invalidate the operating licence, but also the insurance cover. Consumers can find this information either in the registration certificate of their car (Part I under “Tyres”) or on the tyre sidewall of their old tyre. The size specifications for summer and winter tyres may differ here.

Drivers can find the approved tyre size in the so-called tyre code, which consists of numbers and letters. For example, the combination could be “175/65 R 14 91 T”, which means the following when decoded:

- 175: The first digits before the slash stand for the tyre width in millimetres. In this case, the tyres would be 175 millimetres wide.

- 65: The number after the slash refers to the ratio of tyre height to tyre width in percent. In this case, the height is 65 percent of the nominal width.

- R: The following letter indicates the type of tyre construction. R stands for radial tyres, which are now the norm.

- 14: The next number indicates the rim diameter in inches. This means that rims with a diameter of 14 inches are required.

- 91: The number 91 expresses the load index of the model (here 615 kilograms).

- T: The letter V indicates the maximum permitted speed, which in this case is 190 kilometres per hour.

But what exactly is behind the respective marking?

The tyre width

The tyre width is given in millimetres and ranges from 125 to 335 millimetres for ordinary passenger cars, increasing in 10-millimetre increments. The wider the tyres, the better the grip and the shorter the braking distance. At a speed of 100 kilometres per hour, for example, a 225-millimetre-wide tyre comes to a halt five metres earlier than a 185-millimetre-wide model. With wider models, however, the risk of aquaplaning increases because more water has to be displaced. In addition, the rolling noise is louder with wider tyres, which is due to the fact that more rubber is in contact with the road surface.

The aspect ratio

Expressed as a percentage, the tyre cross-section expresses the height-to-width ratio of the tyres. The lower the percentage, the lower the tyre sidewall. Wide tyres usually have a low cross-section, which makes them relatively flat. However, since the air cushion under the rim has less volume, riders feel bumps more clearly. If the value is 50, the tyre height is half the tyre width. Experts often use the term 50 for this.

The construction type

In terms of construction, there are three different types of tyres: Radial, bias and run-flat tyres. For modern tyres, only radial tyres (R) or run-flat tyres (RF) are available. In the former, radially arranged threads form the substructure of the tyre on which the rubber tread rests. In the wet and in curves, they have better running properties than cross-ply tyres. They also have a lower rolling resistance and cause less fuel consumption. Cross-ply tyres (D) are only found on vintage cars, as this type of construction was only common until the 1960s. Mixed tyres are not permitted; the construction of all four tyres must be identical.

The rim diameter

The diameter of the rim is measured diagonally from rim edge to rim edge and is given in inches. Common measurements for car tyres are between 10 and 20 inches, or 315 to 440 millimetres. Tyres for large rims usually have a smaller aspect ratio, which makes them harder and less comfortable to drive. Smaller rims with a large aspect ratio cushion bumps better, but offer less grip due to their rather small contact area.

The load capacity index

The load index, also known as the load index (LI), informs drivers about the maximum load of the tyres at a pressure of 2.5 bar, i.e. the highest permissible weight with which the tyres may be loaded. Each number is assigned a value in kilograms. A load capacity index of 80, for example, indicates a maximum load capacity of 450 kilograms. If the load capacity is exceeded, the tyre may be damaged, increasing the risk of an accident. Additional indications such as “Reinforced”, “Extra Load” or “XL” identify tyres with a particularly high load capacity index, for example for vans, vans or off-road vehicles.

The speed index

The maximum permitted speed for the vehicle is indicated by a code letter and ranges from F, which stands for 80 kilometres, to Y, which means 300 kilometres per hour. The symbols VR (over 201 kilometres per hour) and ZR (over 240 kilometres per hour) indicate the maximum speeds of older vehicles, which are generally no longer manufactured today. For summer tyres in particular, the value on the vehicle registration certificate may be higher but not lower than the prescribed speed index (sometimes also speed index) in order to avoid damaging the tyre. Winter tyres, on the other hand, may be slightly lower than the value, but by no means higher.

Complete package, economy version or puncture system: The designs

Summer tyres come in different designs: While some designs are a complete package, i.e. tyre and wheel rim, others require the purchase of an additional rim. With so-called emergency tyres, the driver can still cover a certain distance after a puncture and complete loss of pressure, for example to the nearest garage. There are basically three types of summer tyres:

Complete wheels

Complete summer wheels consist of tyres and rims. Consumers have the choice between the high-priced but stylish aluminium rims and the more robust and at the same time cheaper steel rims. Since users only have to unscrew the wheels and screw them back on, changing tyres seasonally is quite easy. There is no need to pull the tyres off the rims, which saves consumers not only time but also money, as they do not have to go to a workshop but can change the tyres themselves. However, they have to dig deeper into their pockets for the purchase.

Summer tyres

Summer tyres require the additional purchase of a rim, as this is not included in the scope of delivery. The tyre change can only be carried out in a garage or at a tyre dealer and is correspondingly expensive (about 40 euros). The saving on the purchase is therefore offset by the regular expenses. It would be practical to get a second set of rims at the same time.

Runflat tyres

Run-flat tyres (RFT for short) have emergency running properties due to their self-supporting, reinforced sidewalls, which make it possible to continue driving at speeds of up to 80 kilometres per hour, at best until the next workshop, in the event of a puncture. Accordingly, users do not have to change a punctured tyre immediately. However, they are considerably more expensive than ordinary summer tyres.

The subtle differences: Winter tyres vs. summer tyres

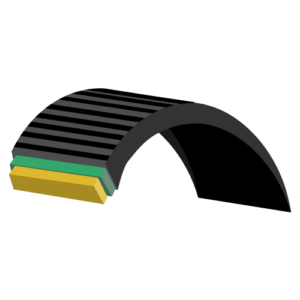

A tyre consists of several layers, which together ensure the best possible stability and strength. Although the composition differs depending on the type of tyre, all tyres consist of these five elements:

- Tread: This is the part of the tyre that is in direct contact with the road surface. It consists of a tread – provided with a profile and an underlying stabilising layer – and is largely responsible for the driving characteristics of the tyre.

- Carcass: The carcass is the supporting structure that holds the tyre together. It usually consists of one or two layers of fabric embedded in the rubber and acting as a strength member. The fabric is composed of synthetic fibre, synthetic silk and steel wire.

- Sidewall: The sidewall is the part of the tyre that protects the carcass from the outside. Because it is relatively thin, it can absorb shocks well, which increases driving comfort.

- Bead: The tyre bead, also called the tyre foot, connects the tyre to the rim by pressing firmly against the rim flange. Inside the bead there are usually several cores made of steel wire that stabilise it. On top of this sits the core rider made of rubber.

- Inner layer: The inside of the tyre is covered with a sealing layer. Thanks to the special rubber coating made of butyl rubber, the inner liner (also called inliner or innerling) prevents air from escaping to the outside.

Depending on the condition of the road surface, temperature and humidity, the demands on the tyres change. In order to cover these as broadly as possible, the industry today provides different types of tyres. Car tyres are therefore designed to withstand the weather and road conditions of the respective season. While summer tyres are designed for use on dry or even rain-soaked roads, winter tyres have to cope with the weather of the cold season and be suitable for slush, ice and snow. The so-called all-season tyres or all-weather tyres, which can be used permanently, are a compromise. Although these tyres do not need to be changed every six months, their performance on dry, wet and snow-covered roads is worse than that of winter and summer tyres. The German Automobile Club (ADAC) has also conducted tests on all-season tyres and recommends all-weather tyres to drivers who live in temperate climate regions and mainly drive in urban areas.

Winter tyres vs. summer tyres

But what exactly is the difference between summer and winter tyres? Mainly, they differ in terms of their tread and material composition. Winter tyres not only have a greater tread depth, but also sipes, the large number of which ensure better interlocking. Their tread compound consists of a soft rubber that remains flexible at low temperatures to ensure stable grip on the road. In addition, since 1 January 2018, all winter tyres require the Alpine symbol to be officially considered suitable for winter use.

To withstand high temperatures while providing safety in the rain, summer tyres differ from the winter version by their harder rubber compound. For low abrasion, a firm grip and a short braking distance, the rubber must be tough. Summer tyres do not soften in the heat and thus have good grip even at higher speeds on hot summer days.

The treads are also designed differently. They are characterised by lower rolling resistance and are much quieter. Since the grooves are smaller and the tread does not have sipes, it is more stable. Due to the flat, rather closed tread, the contact area of summer tyres to the ground and thus their grip is larger. The wide longitudinal and lateral grooves are similar to a drainage system: they channel water away from the tyre’s contact patch, shortening wet braking distance and reducing the risk of aquaplaning.

Tyre pressure, storage and fitting: What to consider after purchase?

Even after buying summer tyres, there are a few points to consider. For example, how high should the pressure be? What about a spare wheel? And what is the best way to store the tyres so that they last as long as possible?

Maintaining the pressure: Regular checks are essential

To ensure that motorists drive not only comfortably but also safely, they should regularly check the tyre pressure. If the inflation pressure of summer tyres is too low, tyre damage, reduced driving stability and longer braking distances are often the result. If the tyre pressure is too high, on the other hand, driving comfort suffers due to low damping. In addition, cornering is much worse. With the right pressure, drivers even save money: as the pressure decreases, fuel consumption increases, while the service life of the tyre decreases.

Consumers can find the information on tyre pressure in the fuel filler cap or in the door frame on the driver’s side. Depending on the load, they need different pressures for the front and rear tyres. Ideally, the values should not be exceeded by more than 0.3 bar. In this case, the car will have slightly harder suspension, but the steering ability will be better and the braking distance shorter. The check should always be carried out on cold tyres, because when they heat up, the air pressure also increases. Appropriate measuring devices can be found in most petrol stations.

The fifth wheel on the car: Don’t forget a spare tyre

Carrying a spare wheel is not required by law. However, since it can happen at any time that one of the tyres rolls over a nail or a shard and bursts, it is advisable to always carry a spare tyre – especially if the summer tyres are not run-flat models. This keeps drivers mobile in the event of a puncture and saves the cost of towing. The other side of the coin: the extra weight increases fuel consumption. In addition, the storage space is considerably limited.

A distinction is made between a full-size spare wheel, which looks exactly like the other wheels and saves a trip to the workshop in the event of a breakdown, and an emergency wheel, which is smaller than the other tyres and has to be inflated to the appropriate size. A spare wheel saves storage space compared to the classic spare wheel, but is only approved for temporary use. The spare tyre must also be checked regularly for proper functioning.

Cool, dry and dark: The right storage

In spring and autumn, the question of proper storage of seasonal tyres arises. In order for summer tyres to last as long as possible, their owner must store them in a certain way. Summer tyres without rims should at best be stored upright on dry, clean ground and rotated slightly every few months. The ADAC advises storing them in as dark a place as possible to protect the rubber from UV radiation, which would accelerate the ageing process. Ideally, complete wheels should be stacked on top of each other, possibly with a cardboard box between the individual tyres. Tyre bags, rim trees and wall brackets may also be recommended for storage.

Before storing, it makes sense to prepare the tyres accordingly:

- Clean the tyres thoroughly and then remove the cleaning agent with plenty of water.

- Check the tyres for any foreign objects and damage.

- Measure the tread depth to ensure that it is above the minimum value.

- Increase the tyre pressure by 0.5 bar compared to the manufacturer’s specification, as tyres lose pressure even when they are not driven.

The service life: How long do summer tyres last?

To be able to determine the tread depth, the tyres are equipped with an indicator. This so-called wear indicator can be found on the edge of the tyre under the letters TWI (“Tread Wear Indicator”), sometimes also under the printed company logo. At the level of these markings there are small protrusions in the tread grooves. As soon as the tread has worn down to this level, the minimum depth has been reached and it is time for new tyres.

Although the law does not stipulate a maximum age for car tyres, since the material deteriorates over time, TÜV and ADAC advise changing them after six years at the latest. Even if the tyres have hardly been used, UV light, heat and moisture affect the material over time, making the rubber compound hard and brittle.

When exactly a change is necessary, however, always depends on driving behaviour, care and the number of kilometres driven. Frequent drivers need to change their tyres more often. If you want to take care of your tyres, you should avoid heavy acceleration, heavy braking and fast cornering. With a calm, careful driving style, tyres can last up to ten years.

The wheel of time

In 1830, the Goodyear company discovered rubber vulcanisation – a process of great importance in tyre manufacturing. 57 years later, John Boyd Dunlop developed the first pneumatic tyre. Finally, the Michelin brothers invented the first demountable tyre in 1891. Today, Goodyear, Dunlop and Michelin are still among the leading tyre manufacturers, along with Continental, Falken, Hankook, Nokian and Pirelli.

Images 1-12: © FinalCheck

9 reviews

9 reviews